Proudly veteran owned. Made with ❤️ in Phoenix, AZ.

Need something that no one has yet? Expedited custom development is also available.

MULTI-CHANNEL READY

Seamless integrations to all top marketplaces, shipping carriers & platforms!

%20(1).png?width=150&height=150&name=Copy%20of%20Copy%20of%20Untitled%20Design%20(1)%20(1).png)

.png?width=150&height=150&name=Integration%20Logos%20(1).png)

.png?width=150&height=150&name=Untitled%20design%20(44).png)

%20(1).png?width=150&height=150&name=Copy%20of%20Untitled%20Design%20(8)%20(1).png)

.png?width=170&height=160&name=Untitled%20design%20(41).png)

.png?width=150&height=150&name=ShipRush%20(1).png)

.png?width=155&height=155&name=Untitled%20design%20(42).png)

.png?width=150&height=150&name=Copy%20of%20Untitled%20Design%20(7).png)

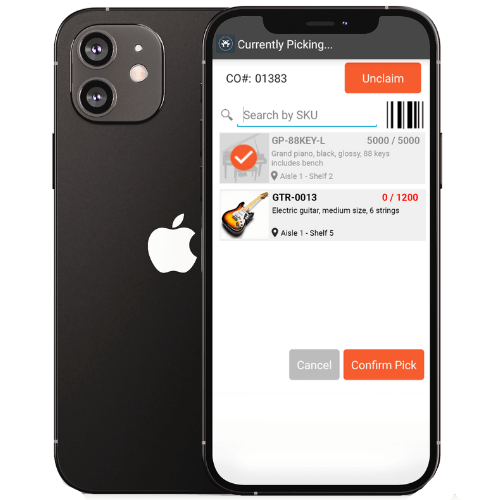

MOBILE APP

When using our app, you can ...

- Always have a real-time pick list in the palm of your hand.

- Scan barcodes with any phone/tablet.

- Work from where it is more efficient. Ditch desk and work anywhere.

- Conduct cycle counts on the go.

- Request warehouse transfers to bring your stock to optimal levels.

ZENVENTORY MAKES IT EASY

Your success is guaranteed.

Let’s be honest, if software isn’t easy to use, your team probably won’t use it.

That’s why we built Zenventory to be easy to configure and even easier to use (even for the fastest-growing e-commerce teams). We’ll be along for the ride every step of the way to ensure you are successful in getting the value you need from our software.

In just 4 steps, you will be up and running with Zenventory!

Step 1

Get a demo or free trial

Step 2

Meet your onboarding manager

Step 3

Connect integrations and load your data

Step 4

Go live!

"Not all inventory systems take care of everything needed to run a business, Zenventory does."

.png)

"Zenventory makes SHIP happen for us."

"Zenventory has been instrumental in our mission to provide the most modern tools to our customers."

OUR TEAM IS STANDING BY

World-class support.

Real live humans!

Nothing is worse than needing help in a hurry and finding that it isn’t readily available. That’s why we invest heavily in our service team, and we average less than one minute of hold time for inbound calls during business hours.

Our friendly team of Phoenix-based technical support experts (real live humans!) are standing by to help if/when you need us.

April 26, 2024

TikTok Ban Bill Passes: What Does It Means for E-Commerce

Discover the implications of the TikTok ban bill on e-commerce brands, social commerce trends, and customer behavior.

Read more

April 24, 2024

Mastering Lot Tracking: The Key to Efficient Inventory Management

Discover the importance of lot tracking in inventory management, including best practices & technological solutions.

Read more

April 19, 2024

Boosting Brand Profits with YouTube's New Shopping Features

Boost brand profits with YouTube's new shopping features. Explore how creators can drive sales through shoppable content and global reach.

Read more

%20(1)-1.png?width=500&height=321&name=Untitled%20design%20(49)%20(1)-1.png)

.png?width=100&height=100&name=Customer%20Logos%20(1).png)

.png?width=100&height=100&name=Pakmo%20logo%20(1).png)

.png?width=110&height=110&name=Vitality%20Medical%20-%20Updated%20(1).png)

.png?width=150&height=150&name=Vendor%20Management%20-%20Small%20Image%20(1).png)